X12

Brass (42%Zn)

Composition: Cu-42%Zn.

Processing: Sand casting, Annealing (800ºC-1h), slow cooling until 600ºC and water quench.

Etching: 30 s immersion in FeCl3 alcoholic solution.

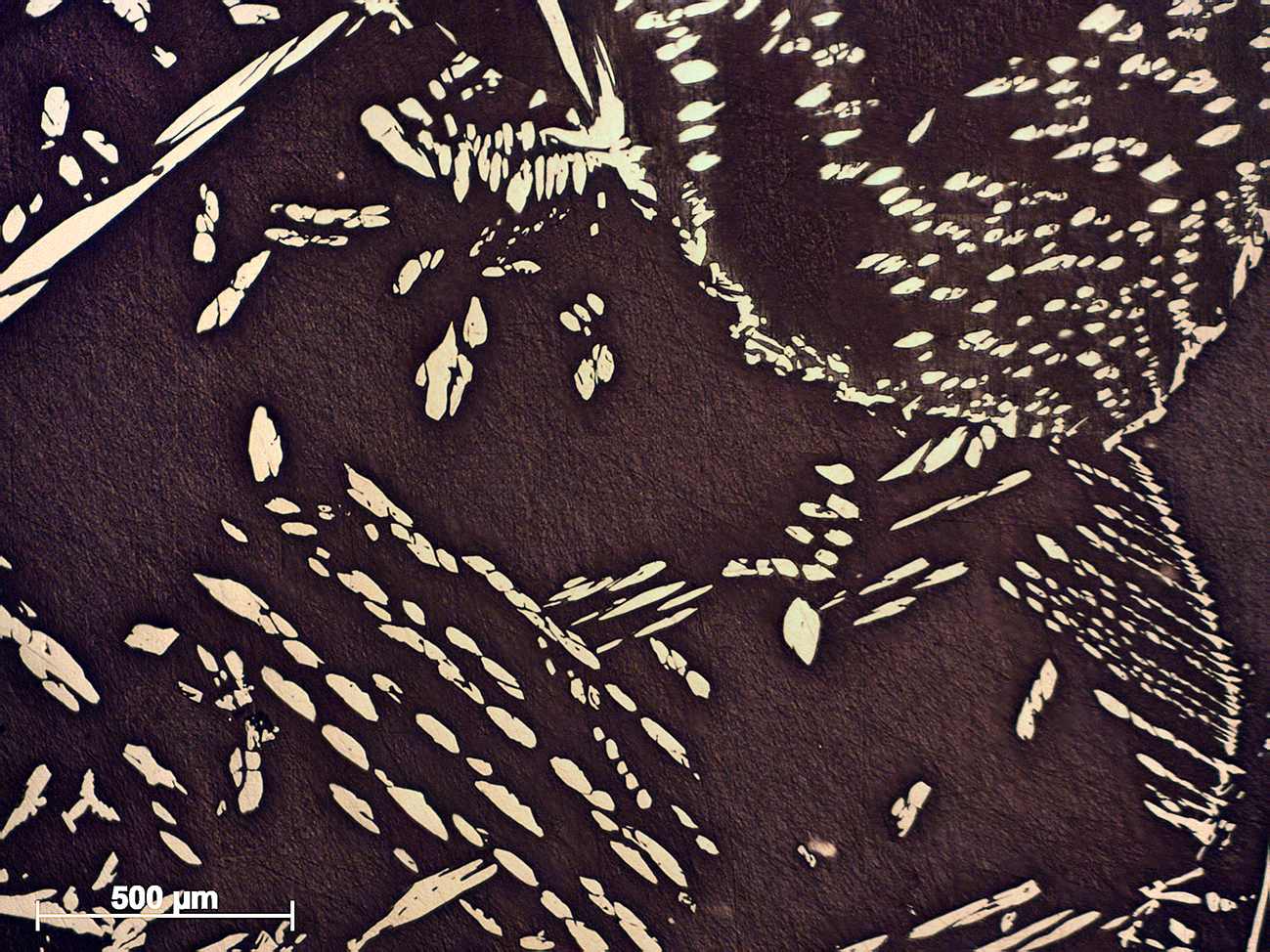

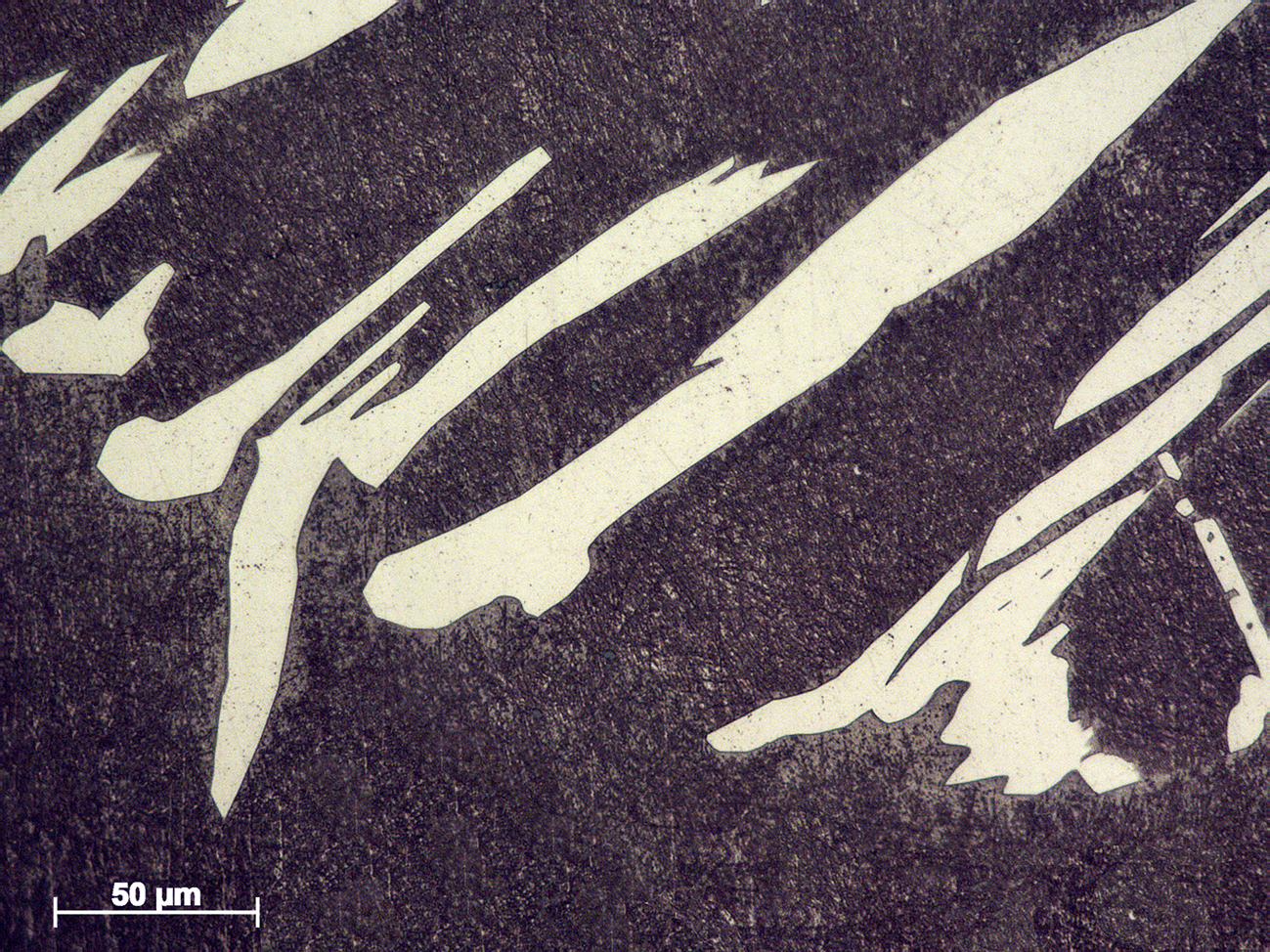

Brass with the same composition as X10 and X11 specimens, but with a different heat treatment. The macrograph reveals large grains of different tonality and precipitation of a secondary phase. Grain coarsening occurs during annealing at 800ºC in the monophasic β field (see Cu-Zn phase diagram). Slow cooling until 600ºC produces precipitation of coarse needles of α phase. The final quench from 600ºC avoids diffusion. Therefore, the final microstructure consists of supersaturated β grains and a smaller amount of α needles than the one expected after slow cooling.

Cu-Zn diagram

This work is licensed under a Creative Commons Attribution-NonCommercpial-ShareAlike 4.0 International