ROBUST INTERFEROMETRIC MICROTHERMOMETER WITH WIDE DYNAMIC RANGE

|

Description |

The Universidad Complutense de Madrid, in collaboration with researchers from the Universität Bremen, has developed a robust and reliable measurement system that is operational in a wide range of temperatures, from cryogenic temperatures to several hundred degrees Celsius, while maintaining the ability to obtain local temperature readings remotely, that is, at a certain distance from the environment with which the probe is in contact.

The microthermometer and its manufacturing method are protected by a Spanish national patent application (ES2980538 ) which can be extended to other countries.

|

How does it work |

The search for accurate and non-invasive methods for temperature measurement is a continuing challenge in scientific exploration and technological progress, as temperature is a key aspect of many fields ranging from healthcare (e.g. monitoring and treatment of cancer cells) to electronic devices (particularly due to heat issues related to miniaturization, which can lead to failures) to environmental studies.

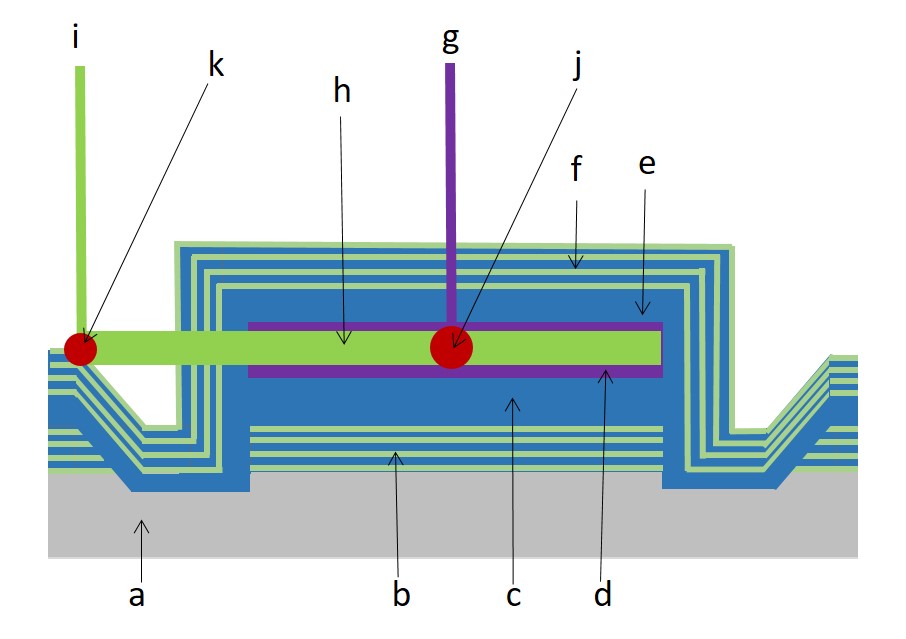

Figure 1. Schematic of the microthermometer structure and operation: (a) bulk substrate, (b) DBR structure, (c) Sheet composed of a low refractive index material that allows guiding the light emitted by the nanowires or microwires (d) nanowire or microwire ; (e) Sheet deposited after deposition of nanowires or microwires, composed of a low refractive index material that allows guiding the light emitted by the nanowire or microwire ; (f) DBR structure after deposition of nanowires or microwires; (g) excitation laser; (h) light guided by the nano- or microwire; (i) position of the target to collect the guided light; (j) excitation point of the microwire; (k) collection point .

One way to measure temperature remotely is luminescence thermometry, based on temperature-induced changes in the spectroscopic properties of a given material system. There are a wide variety of luminescence thermometry techniques, which differ in materials, mechanisms, operating range, and resolution or sensitivity. Depending on the application requirements, certain thermometers are more suitable than others. Generally, there are certain obstacles related to reproducibility and reliability that have prevented their widespread use until now.

The new microthermometer is a luminescent and interferometric microthermometer based on chromium-doped gallium oxide (Ga2O3:Cr) nanowires or microwires delimited by a trench on both sides of the elongated microstructure and characterized in that the entire structure is covered by a sheet, in turn composed of a layer of Al2O3 and a nanometric structure of distributed Bragg reflectors (DBR) formed by two transparent materials. The microthermometer measures the temperature in a simple way through a dual transduction mechanism, luminescent and interferometric.

The microthermometer manufacturing method combines the obtaining of nanowires or microwires, in this case by thermal evaporation, with two techniques that result in the DBR structures that encapsulate the nanowires or microwires to form optical microcavities: one, the deposition technique, such as ALD (Atomic Layer Deposition), and the second, the focused ion beam etching technique (FIB).

|

Advantages |

The developed microthermometer combines robustness with respect to physical contact, precision, reliability and the possibility of operating in a wide temperature range (from cryogenic temperatures up to several hundred degrees Celsius). In addition, easy calibration has been demonstrated. Finally, the device can operate under harsh conditions (such as high intensity excitation laser radiation) or in some liquids, thus it can be used in different industrial and environmental applications as well as in certain biological applications.

The microthermometer fabrication method allows for the fabrication of more than one microcavity with identical DBRs on different nanowires or microwires on the same substrate, allowing the use of more than one temperature sensor on the same substrate (which is useful, for example, if the main sensor starts to fail).

|

Where has it been developed |

Both the microthermometer and its manufacturing method have been developed in the Department of Materials Physics of the Faculty of Physical Sciences of the Universidad Complutense de Madrid by the research group specialized in Physics of Electronic Nanomaterials in collaboration with researchers from the “Solid state materials” group of the Institute of Solid State Physics at the Universität Bremen. Both research groups have experience in collaborating with different universities and public research organizations, both national and international, as well as with private companies, in their research work.

|

And also |

The UCM research group has extensive experience both in the synthesis of oxide nanostructures (nanowires, nanotubes, nanoparticles, nanomembranes, nanocomposites...) and the characterization of these electronic and photonic nanomaterials, oriented to various fields of application such as light emission, photodetectors, energy generation and storage, chemical sensors or photocatalysis.

|

Contact |

|

© Office for the Transfer of Research Results – UCM |

|

PDF Downloads |

|

Classification |

|

Responsible Researcher |

Emilio Nogales Díaz: enogales@ucm.es

Department: Materials Physics

Faculty: Physical Sciences