ELECTROCHEMICAL MONITORING OF CORROSION A HIGH TEMPERATURE IN MOLTEN SALT PRESENCE

|

Description |

This technology allows monitoring by electrochemical impedance techniques, the corrosion produced in materials when subjected to high temperatures and in the presence of molten salts such as carbonates and nitrates.

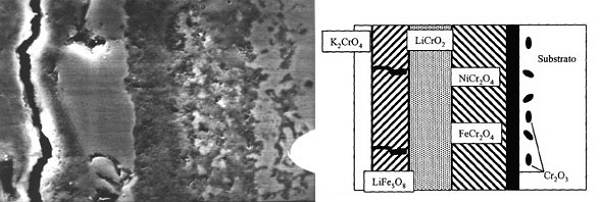

On the left, cross section of steel 310S left 70h in molten carbonates at 650°C in air (micrograph). On the right, an explanatory diagram of the steel corrosion.

|

How does it work |

The technique involves the installation, at certain points that suffer such severe corrosion, of sensors that are connected to an electrochemical impedance equipment. This allows that, for multiple channels, it can be monitored in real time the corrosion phenomena in terms of speed and in terms of its mechanism. The minimum interference technique in the phenomenon makes the data recorded to have a minimal error. It can be applied to portable equipment.

|

Advantages |

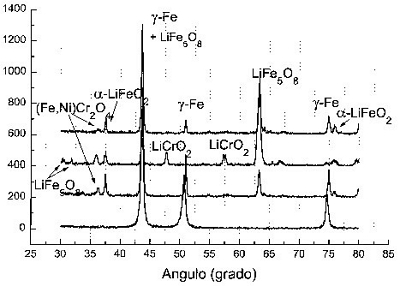

X-ray spectra q-2q on the surface of stainless steel 310S after 0, 30, 70 and 120h.

At present, there is no in-situ and real-time monitoring of corrosion suffered by certain industrial equipment, by the corrosive action of molten salt at elevated temperature, a phenomenon called "catastrophic corrosion".

The main advantage of monitoring is based on using the electrochemical impedance technique as the basis of measurement, a technique that does not change the system, a technique that is not destructive.

In turn, it allows to identify the type of corrosion is taking place: generalized or localized. And in the case of localized corrosion, it would give a semi-quantitative evolution of corrosion to more or less bites, for example.

|

Where has it been developed |

This technique has been developed in the Materials Science and Metallurgical Engineering Department, Faculty of Chemical Science at the Surface Engineering and Nanostructured Materials Group, ISMN (No. 910627). This group of researchers has an extensive experience from 25 years in the investigation of phenomena of corrosion at high temperature in the presence of molten salts. This experience, with the technique of electrochemical impedance (EIS), has resulted in the development of sensors/elements that allow real-time monitoring, and low-cost equipment, instantaneous corrosion rate and the corrosion mechanism (localized or generalized). This technology is in its final phase of development and implementation, so it could be applied in the short term in the following industries:

- Generation of energy (fossil fuels).

- Industrial and aeronautical gas turbines.

- Incineration of waste.

- MCFC Fuel Cells.

- Concentrated solar plants, CSP.

|

And also |

The services that can be provided by the Surface Engineering and Nanostructured Materials Group, ISMN (No. 910627), which is developing this technology, are as follows:

- Adapt the technology to the specific customer problems.

- Carry out technical feasibility studies for a particular application.

- Possibilities of technical assistance after purchase.

- Training for the use of the technology in question.

- Monitoring corrosion at high temperature.

- Life-cycle assessment LCA.

- Analysis of failures in service.

|

Contact |

|

© Office for the Transfer of Research Results – UCM |

|

PDF Downloads |

|

Classification |

|

Responsible Researcher |

Francisco Javier Pérez Trujillo: fjperez@ucm.es

Department: Material Sciences and Metallurgic Engineering

Faculty: Chemical Sciences