DAMASCO STEEL

|

Description |

Fabrication of melee weapons, cutlery in general and sports equipment by hot forging with Damascus steel with excellent mechanical characteristics against abrasive wear and a very aesthetic surface.

In today's industry superfirm carbon steels never reach contents above 1.4% carbon in mass. However, the legendary Damascus steel far exceeds this percentage, ranging from 1.4 to 2.1% of carbon in mass. The current metallurgical industry has not been able to forge this type of steels of great mechanical performance and low price. However, we have managed to uncover the secret of the forging of the steels of Damascus.

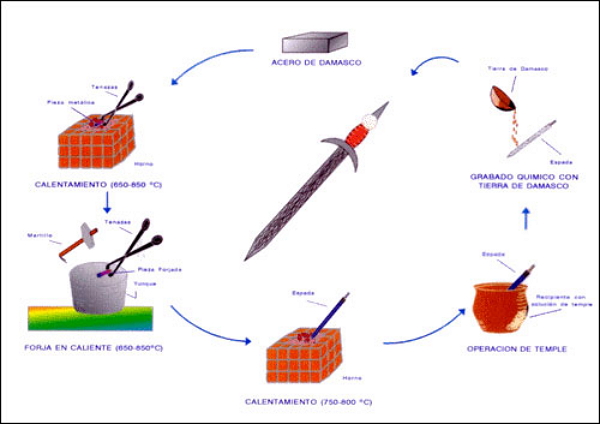

Forging process of Damascus steel and example of finished knife.

|

How does it work |

The hot forging at low temperatures, between 650 and 800 ° C, after superficial carburizing in a very thin surface film, allows to form the pieces with the most irregular forms. This forge crushes the primary iron carbides by dividing them by the steel matrix, achieving a high resistance to wear due to the massive presence of these and excellent toughness.

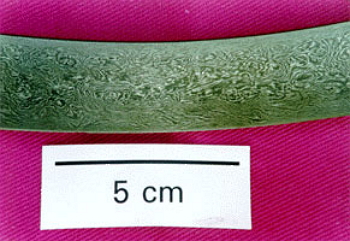

In addition, a very esthetic surface can be achieved if the steel is heat treated at high temperatures followed by slow cooling, prior to hot forging. The control of the heating and cooling allows to thicken the carbides to an adequate value, which makes after the forge, and after a slight chemical attack, become visible forming sinuous tracing bands of great beauty.

Schematic of the process of forging and hardening of a sword of Damascus steel.

|

Advantages |

"Waters" characteristic of Damascus steel

The advantages of Damascus steels compared to other carbon steels or alloys is their high wear resistance which allows them to have a cutting edge permanently, together with good mechanical strength and toughness. To these unique mechanical characteristics, in applications of cutting or machining of other metals, the beauty and the magic of its surface is united, something that has made them legendary in the celebrated swords of Damascus.

|

Where has it been developed |

Group of Mechanical Technology and Archaeometallurgy. Department of Materials Science and Metallurgical Engineering. Faculty of Chemical Sciences.

This Research Group has great experience and international prestige in archeometallurgy, nuclear technology and conventional mechanics.

Studies on archaeological metal pieces are being highly sought after by today's industry. Organisms such as the Army Museum, the Provincial Council of Cordoba, the City Council of Obejo (Córdoba), and the Commission of Professional Archaeologists in Madrid request our services to study and rescue valuable archaeological pieces such as the Tizona sword or Mehemet Ali's cutlass, As well as for the dating and study of the deterioration and origin of the most varied metallic objects.

In the field of steel design for various applications we have a proven experience. Thus, we have rescued old technologies such as Damascus steel presented here or the Toledo Steel, not forgetting the current steel between which we have designed a type that is possibly the most resistant and hard of those that exist today.

|

And also |

From the Metallurgical Industry to the Electronic Industry, passing through Aerospace, we have researched, advised and exchanged knowledge and technologies for more than a decade.

In the nuclear industry our expertise in the field of nuclear fuels has enabled us to investigate and advise institutions such as the Central Bureau for Nuclear Measurements (Geel-Belgium), Transurane Institute (Karlsruhe-Germany), Institut for Avanced Materials (Ispra - Italy-).

Within the field of advanced materials we are working on the study of corrosion, metallography, mechanical design, destructive and non-destructive mechanical tests with the Clausthal Universität and Fraunhofer Institut für Chemische Technologie (Pfinztal-Germany).

The Archaeometallurgy group has great experience in adapting the technology to the specific problems of the customer and is available, due to its long experience, for training in the use of the technology in question, as well as to offer technical assistance after purchase.

|

Contact |

|

© Office for the Transfer of Research Results – UCM |

|

PDF Downloads |

|

Classification |

|

Responsible Researcher |

José Antonio Criado: antoniocriado@quim.ucm.es

Department: Materials Science and Metallurgical Engineering

Faculty: Chemical Sciences