CHARACTERIZATION OF ADSORBENTS: DYNAMIC TEST OF ADSORPTION/DESORPTION

|

Description |

This technology allows the study, at laboratory scale and in dynamic regime, the separation efficiency of adsorbents in the liquid phase, determination of their characteristic parameters of adsorption / desorption as well as their useful life. At present, two automated plants are operating, allowing cyclic experiments using small amounts of adsorbent (10-30g) under very different pressure conditions (1-50 bar) and temperature (25-350ºC).

The modeling of the experimental data allows the design and scaling of the separation unit, as well as the optimization of the operating conditions of the same. It has its own software to simulate cyclic adsorption (SMB) processes with the studied adsorbent.

The technology can be used in complex separations of compounds with similar boiling temperatures or having azeotropes or thermosensitive molecules by the use of a selective adsorbent. In this sense, it is a suitable technology for the separation and purification of pharmaceutical products by SMB. Its main advantage is its low energy consumption and the absence of waste.

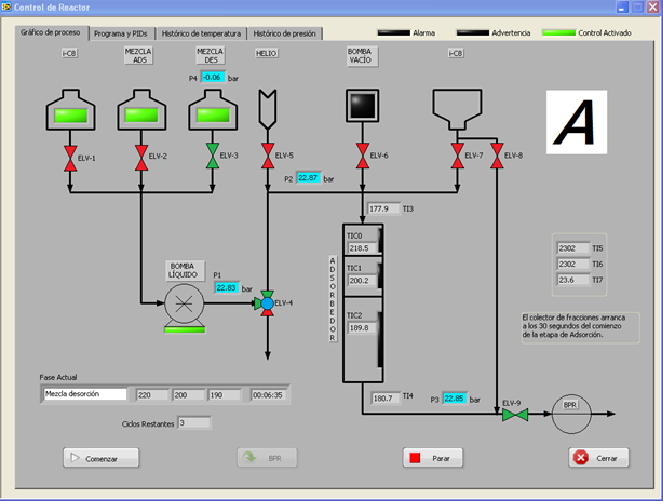

Control and data acquisition unit of the experimental installation developed in Labview.

|

How does it work |

A gas feed line allows activating the adsorbent located in the adsorption/desorption bed, where necessary. By feeding the separating agent or the desorbent to the bed by means of a pump and analyzing by gas chromatography the effluent from the bed, the corresponding breaking curve is determined, from which the characteristic parameters of the adsorbent material in adsorption / desorption will be deduced. The cyclic repetition of these stages and the calculation of the variation of their characteristic parameters with the number of these, allow to estimate the degree of deactivation (useful life) of the adsorbent.

By means of modeling of the experimental break curves, fundamental parameters can be obtained on the equilibrium and the adsorption kinetics in the process.

The developed model takes into account important aspects such as the velocity variation inside the adsorber and the variation of the density of the liquid mixtures with the composition in the system, which is not easy to find in other similar models available in the literature.

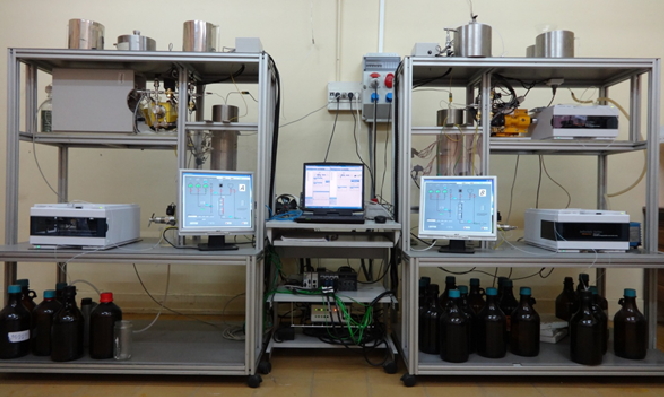

Experimental installations.

|

Advantages |

The main advantages of the developed system are the following:

• It allows to characterize the behavior of adsorbent solids, both in adsorption and desorption in liquid phase, for different processes of separation of mixtures and / or purification of liquid streams, from the corresponding break curves.

• Uses industrial operating conditions (P = 1-50 bar and T = 25-500ºC).

• Small amounts of adsorbent (15 - 30g).

• Rapid deactivation of the adsorbents for the estimation of their life in the process.

• Low power consumption

• Absence of waste

• Continuous operation

|

Where has it been developed |

This characterization technique, as well as the corresponding experimental equipment and the modeling and simulation program, has been developed in the Catalysis and Separation Processes Group integrated in the Department of Chemical Engineering of the Faculty of Chemical Sciences of the Universidad Complutense de Madrid.

The research team that has developed this technique has extensive research experience, supported by numerous scientific articles published in international journals, research projects developed with the Spanish and European administration (CICYT, CAM, BRITE), as well as with the Spanish industry and (PETRESA - a company of the Cepsa group, REPSOL, Elf-Aquitaine, etc.), as stated in their curricula.

|

And also |

Through the developed technology, the Laboratory of Basic Operations of the Department of Chemical Engineering of the Faculty of Chemical Sciences could provide the following services:

• Characterization of adsorbents for separation and / or purification processes in liquid phase.

• Screening of adsorbents for a given liquid phase separation and / or purification process.

• Adsorbent quality control: Determination of the adsorption / desorption parameters from the corresponding breakdown curves and adsorbent life by a fast cyclic adsorption / desorption test.

• Optimization of the operating conditions of existing processes.

• Development of cyclic adsorption separation processes

• Modeling and design of industrial scale units based on SMB technology

|

Contact |

|

© Office for the Transfer of Research Results – UCM |

|

PDF Downloads |

|

Classification |

|

Responsible Researcher |

Mª Ángeles Uguina Zamorano: uguinama@quim.ucm.es

José Antonio Delgado: jadeldob@ucm.es

V. Ismael Águeda Maté: viam@ucm.es

Department: Chemical Engineering

Faculty: Chemical Sciences