Laser surface treatments

Laser surface melting is a well established technology applied to many materials for hardening, reducing porosity and increasing corrosion resistance. Some industrial laser sources have been available for many years, i.e. CO2, Nd:YAG and excimer lasers. In the last years high power diode lasers (HPDL) have been introduced, bringing in the advantage of much higher efficiency, smaller size and reduced maintenance, energy consumption and associated equipment. The costs of HPDL are similar to those of CO2lasers, which are much cheaper than other laser sources. Moreover, HPDL emit at infrared wavelengths, i.e. in the 810 to 940 nm range, shorter than Nd:YAG ones, avoiding inherent problems associated to the 10.6 μm emission of CO2 lasers and to the ultraviolet one of the excimer lasers. Hence, these lasers are promising processing tools for the industry if materials surface properties improve nearly as much as with other laser tools. Cast aluminum alloys and composites are lightweight and show high specific strength and hardness, but their wear and corrosion resistance is limited because of the presence of coarse intermetallic phases in their surface, heterogeneous interfaces between matrix and reinforcement and porosity. Laser surface processing with CO2, excimer and and Nd:YAG lasers provide enhancement of hardness and corrosion resistance. Formation of aluminum carbide in composites with SiC reinforcement during processing is the key problem to avoid because it is a brittle compound that degrades in humid environments.

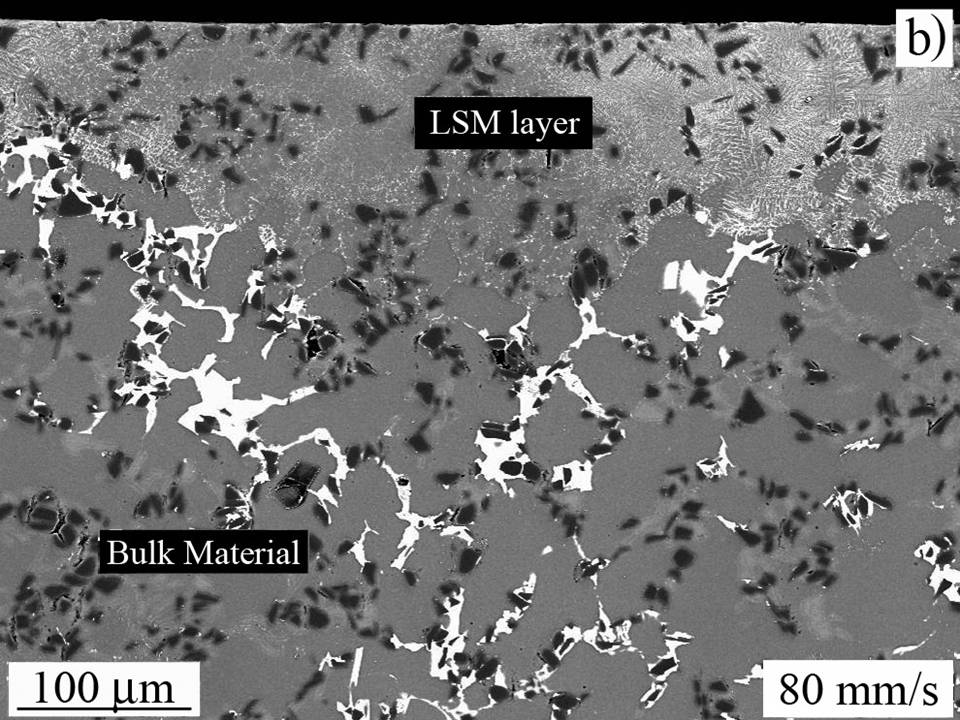

The research line is concerned with laser surface treatments of light materials and steels in order to improve their corrosion and wear resistance.